Automatic hair sticking machine

UNT-ZM

Equipment features:

Younaite after design, more than ten years of production and advanced washing equipment in textile printing industry has become an important and perfect system of cleaning equipment company.

Younaite always pay attention to the market and competition with UNT-ZM automatic dedusting equipment for printing industry, has become the advanced technology products company reform.

UNT-ZM technology is used in textile printing industry, which affirms the high performance, unique and quantifiable processes with different costs, and achieves high quality production.

UNT-ZM is now used in factories around the world to solve the dedusting process before printing.

UNT-ZM continues to improve, the second generation model has launched the market, the new model design is more perfect, more efficient and fully automated to ensure complete self monitoring. It is suitable for different sizes and speeds of circular and flat printing machines.

How to operate

The unique design of UNT-ZM adhesive coating roller, adhesive coating can be optimized according to different kinds of cloth with the adhesive side can operate continuously, first in the dyeing process and can be completed before the dust cleaning head through the unique automatic cleaning, can improve the productivity. The surface of the roller is the glue coating, by lifting table, mechanization and floating, the lifting and fabric mutually adjusted to achieve the best dust removal and rags. The cleaning head oscillation system was patented in the top roller, roller surface adhesion of dust removal, go and rags, and then through the cleaning head back and forth to dust on the drum completely clean up. UNT-ZM automatically reconnaissance roller and fabric speed, allow a variety of production speed, from start to stop do not need manual operation. The second generation of automatic dust removal system of UNT-ZM second generation UNT-ZM can more effectively remove dust and rags, can be used for round or flat net printing and is suitable for the production of different kinds of cloth, speed and width.

UNT-ZM advanced technology includes self vacuum cleaning system, continuous discharge of dusty sewage and reduction of manual operation. The other electronic control system is self - testing to ensure efficient operation. This design is durable and lightweight and easy to install, the most advanced system is the most effective rate of impurity and dust cloth equipment.

advanced

Operator interface with advanced electronic control and clear display panel, full function UNT-ZM. The system also joins self - testing software to ensure continuous operation and efficiency.

The automatic switch system can connect the needs of the printer or the production line to reduce the operator intervention. The other is equipped with multi-function control panel so that the drum cleaning and adhesive application, ensure optimal efficiency and speed.

accurate

The electronic roller cleaning head only occupies a small number of positions, so that the dustpan can play the maximum efficiency, ensure that the dust is continuously cleaned, and connect regularly and comprehensively to clean up, and reduce the occurrence of dust and dust outside the drum.

In order to choose the right and left operation, according to the customer's needs and according to the printing machine and select the right and left operation.

Characteristic

The unique floating design ensures maximum dust removal and does not deform or damage the cloth. The speed of cleaning and dedusting of the drum is easy to adjust, depending on the demand of the cloth.

Factory installation is set to ensure efficiency and start use.

Control

The installation project is simple to reduce the production time, and the drum assembly is easy to clean and reduce the pause time. It is easy to install and check the location on all equipment.

Cover by pneumatic open protective coating adhesive, the drum will automatically rotate in the coating, to paste the surface layer consistency and regularity, reduce the pause time and greatly increase the dust cleaning function, and provides the operator with a comprehensive control.

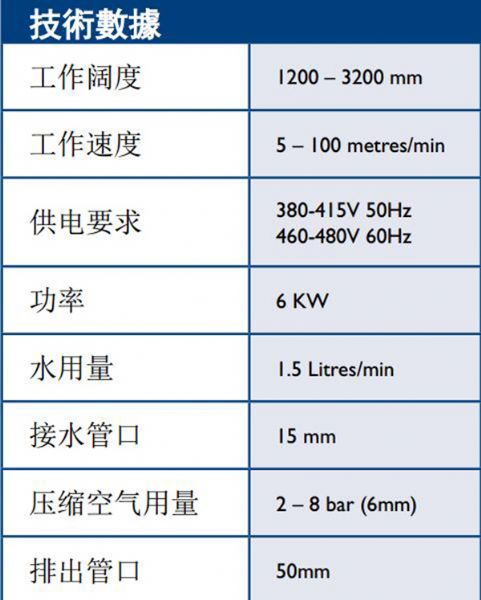

technical parameter

中文

中文 English

English